Polymer Synthesis: New Mechanistic Insights and Catalytic Control

By Allison Tang

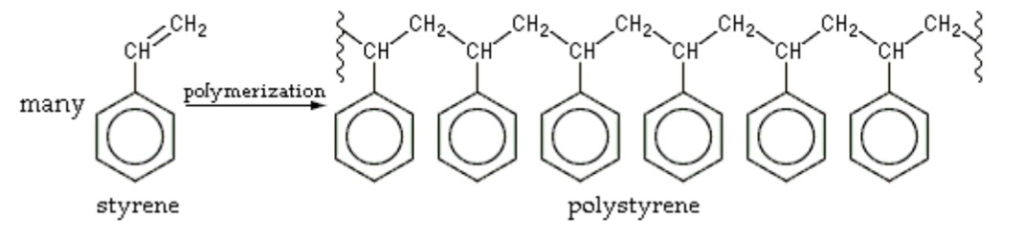

Polymer synthesis is the procedure through which long-chain

macromolecules—polymers—are assembled from small monomer building blocks. As outlined

in Vollhardt & Schore’s Organic Chemistry (2018), polymers are largely produced by addition

polymerization of alkenes, where monomer units are successively added, converting double

bonds into single-bonded backbones. This procedure of molecular assembly forms the basis for

most everyday materials, such as high-strength fibers and biomedical devices.

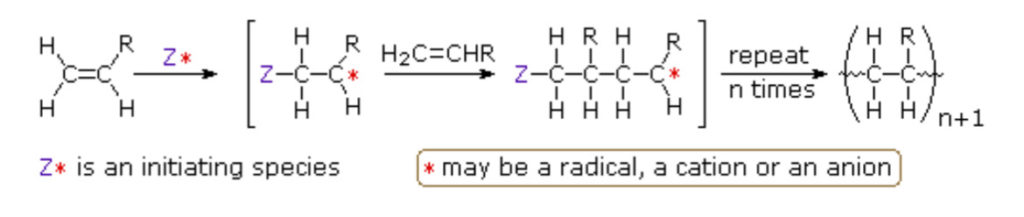

There are two main methods of polymer synthesis: step-growth polymerization and chain-growth

polymerization (addition polymerization) (Reimschuessel, 1975). Chain-growth polymerization

is initiated by a reactive species that activates a monomer. Once activated, new monomers add to

the propagating chain rapidly, one by one. Chain-growth polymerization is widely used for

synthesizing commercially important plastics like polyethylene and polystyrene (National

Polymer, 2024). The efficiency of chain-growth polymerization makes it an excellent choice for

synthesizing polymers with very high molecular weights (Reimschuessel, 1975).

Step-growth polymerization (condensation polymerization) employs monomers with two or

more reactive groups—such as diols, diamines, and diacids—that build up in a series of steps.

Each reaction typically releases a small by-product like water or HCl. Unlike chain-growth, step-

growth polymerization does not require an initiator but relies on the functional groups present on

the monomers. Step-growth polymerization is commonly used in the preparation of nylons,

polyesters, and epoxy resins (Sigma-Aldrich, n.d.).

Conventional polymerization often yields polymers with broad molecular weight distributions

and irregular architectures. However, controlled/living polymerization methods enable chemists

to precisely manipulate polymer structures. An example is Atom Transfer Radical

Polymerization (ATRP), which uses metal catalysts—most notably copper complexes—to

reversibly activate and deactivate propagating chains, ensuring accurate control over molecular

weight and architecture (Sigma-Aldrich, n.d.). Reversible Addition-Fragmentation Chain

Transfer (RAFT) polymerization employs chain-transfer agents to regulate chain growth,

allowing the formation of block copolymers and complex architectures like stars and brushes

(Chiefari et al., 1998). These methods enable scientists to design polymers with predictable

lengths, narrow molecular weight distributions, and specialized shapes.

The arrangement of monomer units in a polymer chain significantly affects its physical

properties. Specific catalysts are employed to manage this arrangement. Ziegler-Natta

catalysts revolutionized polymer synthesis by enabling the production of polymers like

polypropylene with well-ordered isotactic or syndiotactic morphologies, resulting in enhanced

strength and crystallinity (Vollhardt & Schore, 2018). Metallocene catalysts offer even greater

control by using single-site catalysts that precisely regulate polymer chain growth, achieving

uniform molecular weights and superior material properties (National Polymer, 2024).

Additionally, Ring-Opening Metathesis Polymerization (ROMP) opens strained cyclic

monomers and links them into unsaturated polymer chains, a technique used to create synthetic

rubbers and functional polymer networks with tunable mechanical properties (Sigma-Aldrich,

n.d.).

With rising environmental concerns, polymer chemists are focusing on sustainable

alternatives. Polylactic Acid (PLA), derived from renewable resources like corn starch or

sugarcane, is a biodegradable and compostable polymer being marketed as an eco-friendly

substitute for petroleum-based plastics (National Polymer, 2024). Furthermore, sequence-

controlled polymers are synthetic macromolecules built with precisely arranged monomer

sequences. By placing monomers at specific positions on a molecular level, scientists can design

materials with highly specialized functions, from molecular recognition to programmable self-

assembly (Sigma-Aldrich, n.d.).

In conclusion, polymer synthesis is a rapidly evolving field that fuses chemistry and materials

science. From foundational chain-growth and step-growth mechanisms to advanced controlled

polymerization techniques and catalyst designs, scientists now have unprecedented control over

polymer structure, function, and environmental impact (Reimschuessel, 1975; Vollhardt &

Schore, 2018).

Bibliography:

Chiefari, J., Chong, Y. K., Ercole, F., Krstina, J., Jeffery, J., Le, T. P. T., Mayadunne, R. T. A.,

Meijs, G. F., Moad, C. L., Moad, G., Rizzardo, E., & Thang, S. H. (1998). Living free-radical

polymerization by reversible addition–fragmentation chain transfer: The RAFT

process. Macromolecules, 31(16), 5559–5562. https://doi.org/10.1021/ma9804951

National Polymer. (2024, April 18). Synthesis of polymers and resins. National Polymer.

Retrieved August 4, 2025, from https://nationalpolymer.com/blog/synthesis-of-polymers-and-

resins/

Reimschuessel, H. K. (1975). General aspects in polymer synthesis. Environmental Health

Perspectives, 11, 9–20. https://doi.org/10.1289/ehp.75119

Sigma-Aldrich. (n.d.). Polymer synthesis and analysis. Merck KGaA, Darmstadt, Germany.

Retrieved August 4, 2025, from https://www.sigmaaldrich.com/US/en/applications/materials-

science-and-engineering/polymer-synthesis

Vollhardt, K. P. C., & Schore, N. E. (2018). Organic chemistry: Structure and function (7th ed.).

W. H. Freeman. Retrieved

from https://chem.libretexts.org/Bookshelves/Organic_Chemistry/Map%3A_Organic_Chemistry

_(Vollhardt_and_Schore)/12%3A_Reactions_to_Alkenes/12.15%3A_Synthesis_of__Polymers